metal bend test machine|four point bending test : traders The Model BT3 Bend Tester uses a unique method for wrapping the bend specimen around the mandrel. Specimens are forced to conform to the mandrel surface. This is especially useful for . • «Arquivo do Cold Case»• . Ver mais

{plog:ftitle_list}

webBonds Promo Code. Bonds & Me Benefits. Birthday Vouchers. By joining Bonds & Me and signing up for their newsletter, you will get a 10% Bonds coupon codes every year for your birthday. Up to 30% off. You can save 10%, 20% or even 30% on all orders depending on your membership tier.

Bend test machines are typically universal testing machines specifically configured to evaluate material ductility, bend strength, fracture strength, and resistance to fracture. Bend tests tend to be associated with ductile metals .

The Model BT3 Bend Tester uses a unique method for wrapping the bend specimen around the mandrel. Specimens are forced to conform to the mandrel surface. This is especially useful for .Elastic modulus in bending (i.e., flexural modulus), stress-strain behavior, and failure limits in bending all can be obtained using the simple sample geometry of a 3-point bend test. ASTM D790 or ISO 178 covers flexural properties for . 1.1 These test methods cover bend testing for ductility of materials. Included in the procedures are four conditions of constraint on the bent portion of the specimen; a guided-bend test using a mandrel or plunger of defined dimensions to force the mid-length of the specimen between two supports separated by a defined space; a semi-guided bend test in . TestResources manufactures and supplies universal test machines, tensile testers, dynamic testing machines, and much more. Call us today (800)430-6536. A Complete Guide to the Three-Point Bending Flexural Test

There are 4 different types of bend tests that is commonly used in most industries. A guided bend test is where the material is placed horizontally in between 2 supports and then the force is applied right in the middle, ideally bending it into a U shape. A semi-guided bend test is done by bending the material to a specific angle or radius.This machine was designed and developed by Triangle Engineering to bend a welded metal specimen into a 180 degree "U" shape, thereby subjecting the weld deposit to extreme tension, commonly referred to as a bend test. The full range of ferrous and nonferrous bend test requirements of A.S.M.E. Section IX and A.W.S can

what is flexural test

Single-edge notch-bending specimen (also called three-point bending specimen) for fracture toughness testing.. The fracture toughness of a specimen can also be determined using a three-point flexural test. The stress intensity factor at the crack tip of a single edge notch bending specimen is [3] = [() / / + / / + /] where is the applied load, is the thickness of the specimen, is .The types of bend tests discussed are bending ductility tests, bending strength tests (ASTM E 855), bend tests as per EN 12384 and JIS 3130, and computer-aided bending tests. The three standard bending strength tests are the cantilever beam bend test, the three-point bend test, and the four-point bend test.The Electronics Bend Flex Test; Metal Welds Put Through a Guided Bend Test; Wood-Based Products Static Bend Test | ASTM D1037 | Equipment Wood Static Bend Test | ASTM D143 | Equipment Metal Ductility Bend Test Weld Ductility Bend Test Weld Strength Tests using Guided Bend and Tensile Fixtures | Equipment

Flexural testing, or bend testing, is a key part of basic materials characterization. This video discusses the equipment used when performing a bend test and.Find here Bend Test Equipment, Bend Testing Machine manufacturers, suppliers & exporters in India. Get contact details & address of companies manufacturing and supplying Bend Test Equipment, Bend Testing Machine, Bend Test Machine across India.A bend test, also known as the flexural test, is a standardized method employed to assess the ductility, bend strength, fracture strength, and resistance to fracture of materials.This testing methodology involves subjecting a specimen to a controlled bending force to evaluate its resistance to deformation. The bend test is important in construction processes involving . Small-scale bending tests (Fig. 7) provide a simply fixable set-up for anchors characterization in combined shear-bending and even in equilibrium critical application.It is probably the closest combination of stresses to simulate a real-scale bended structure, which is possible through a small-scale test [97].In this case, recovery of characterization data from the .

Find your bending testing machine easily amongst the 447 products from the leading brands (A&D Company, Haida, Instron, .) on DirectIndustry, the industry specialist for your professional purchases. . compression, bending and bending test to metal and nonmetal . Compare this product Remove from comparison tool. universal testing machine .

The CP130604 fixture has a maximum force capacity of 20 kN and is designed specifically for tight radius bend testing of sheet metals in accordance with VDA 238-100. The punch radius, roller diameter, and roller distance are constrained to reduce lab-to-lab variability. . 5 kN Flexure Fixture Equipment Manual 100 kN Flexure Fixture Brochure . While it is easy to imagine why bend testing needs to be performed on rigid materials like plastics (ASTM D790) and concrete (ASTM C1609), in reality bend test applications are common in a variety .It is commonly performed on relatively flexible materials such as polymers, wood, and composites. At its most basic level, a bend test is performed on a universal testing machine by placing a specimen on two support anvils and bending it .TTRBM Rebar Bend and Re-bend Testing Machine is specially designed to test bend resistance performance of reinforced rolling steel bars, building steel reinforcements and steel plates which completely meet the requirement of .

The weld should not fail and the metal should not crack under the stress during bending for an acceptable bend test result. What is the Bend Test in welds, & the Types of Bend Test? The bend test is specified in ASME section 9 and AWS D1.1 for welder testing & weld testing for performance & procedure qualification.ISO 7438, ISO 5173, ASTM E190, ASTM E290 Bending tests are performed for the material flexural properties determination. Visual analysis of the bending behavior of specific metallic components is object of the bending test

A bending machine, also known as a weld bend tester, is often used for welding bend testing. To produce bending, this machine delivers regulated forces to the welded specimen. It typically includes adjustable grips or clamps to secure the specimen, a bending mechanism to apply the necessary force, and measurement equipment to quantify the . During large-radius bending sheet metal yields less than during other types of bending, so springback is greater and difficult to calculate. So a bend test needs to be carried out in order to determine the precise value of the springback, which is dependent on the material and its thickness, and the radius to be obtained. The bend length required will usually depend on the design specifications of a sheet metal part. Bending machines, however, all have maximum widths according to their physical size and configuration. It’s best to seek guidance if your parts are above 2 m as this is a standard sheet and press brake size.Tensile tests are performed on universal testing machines, also known as tensile machines or tensile testing machines. These machines consists of a single or dual column frame equipped with a load cell, testing software, and application-specific grips and accessories such as extensometers.Universal testing machines come in a wide variety of force capacities and can .

Guided bend tests provide a quality control check that helps determine the ductility of weld metal at the face and root of a welded joint. A guided bend test sample containing the weld is located at its center point while being supported by lower anvils. It is bent 180 degrees and the sample is visually checked for cracks or defects. No cracks should appear on the surface greater than .

The 1510 Bend Tester is a mechanical tester used to determine the effects of bending on the elasticity, adhesion and elongation properties of cured coatings on sheet metal. The frame has a bending lever with a roller which pivots on a steel conical mandrel with a diameter from 3.2 - 38.1mm (0.12 - 1.5").Calibration of Mechanical Testing Machines and Apparatus. . E855-21 Standard Test Methods for Bend Testing of Metallic Flat Materials for Spring Applications Involving Static Loading . . E82/E82M-14(2019) Standard Test Method for Determining the Orientation of a Metal Crystal . E766-14(2019) Standard Practice for Calibrating the .

TestResources manufactures and supplies universal test machines, tensile testers, dynamic testing machines, and much more. Call us today (800)430-6536. . There are many industry standards that are followed in metals bend tests. A metal specimen is bent over a mandrel until it breaks or reaches a specific angle. These tests confirm material .

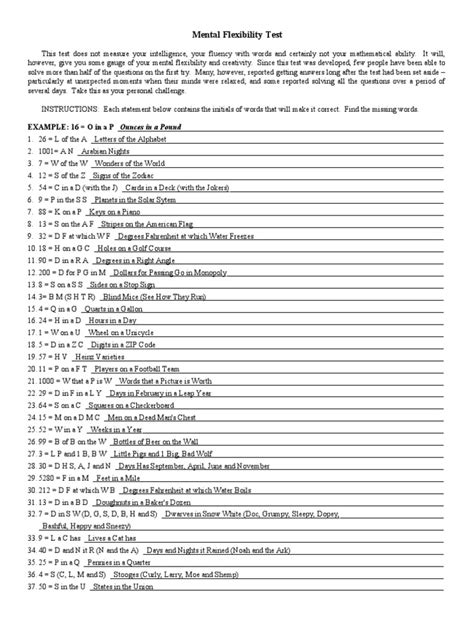

mental flexibility test

WEBComecei a fazer trading em 1981. Em 1986, minha carreira profissional começou. Passei cerca de 5 anos muito difíceis para conseguir consistência, posso dizer que foram os .

metal bend test machine|four point bending test